Enhance Fleet Performance with High-Efficiency Auxiliary Power Units

In today’s competitive trucking industry, fleet operators are under constant pressure to optimize efficiency, reduce costs, and navigate a complex web of environmental regulations. One of the most substantial operating expenses is fuel consumption, a large portion of which is expended not on the highway, but during stationary rest periods for drivers. Unnecessary tractor idling can consume thousands of gallons of fuel per truck annually, accelerate engine wear, increase maintenance costs, and produce emissions that contribute to air pollution and attract regulatory scrutiny.

Auxiliary power units (APUs) emerged over the last several decades to combat these challenges. By providing off-engine power for climate control, cab electricity, and other driver amenities, APUs considerably reduce engine idling, facilitating fuel savings and lower total cost of ownership for fleet operators, while keeping drivers comfortable during their trips.

However, today’s appliance demands require modern power solutions. For example, it is common for a driver to need air conditioning, microwave, CPAP machine, and a host of other electrical devices used in a common home—including air fryers, TV consoles, gaming systems, coffee pots, and more— during their rest period, and not all power units on the market have the capacity to meet these needs. During times of high demand, drivers were previously required to run the tractor engine from time to time to meet these power needs. Fortunately, innovators in the industry are manufacturing devices that take this increased power demand into consideration, addressing these and other concerns.

This white paper explores the operational, financial, and regulatory challenges posed by tractor idling and auxiliary power needs. It then details the advanced solutions that Thermo King® brings to the market with its TriPac® APU portfolio, including the dieselpowered 3rd Generation TriPac and the all-electric TriPac Envidia®. Through advanced engineering, robust performance, and a focus on driver comfort and regulatory compliance, Thermo King APUs empower fleet operators to enhance profitability, improve driver retention and achieve sustainability goals.

Redefining rest stops with auxiliary power

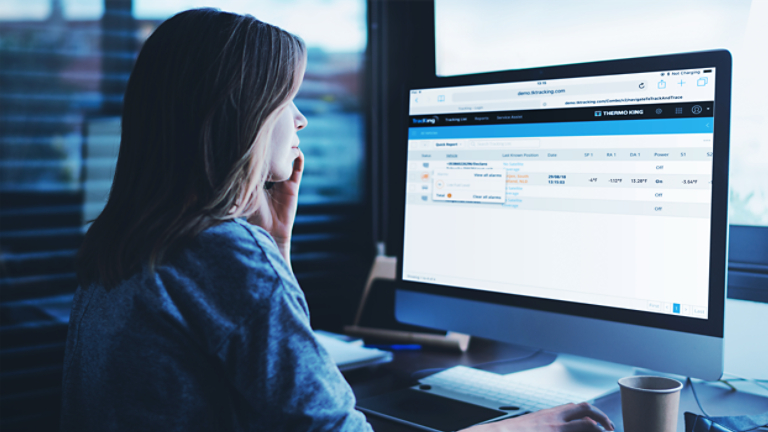

An APU is a self-contained system that provides energy for essential driver needs without requiring the use of the main tractor engine. While parked during rest, loading, unloading, waiting, or other periods, drivers still desire a comfortable and functional living space, just as when they are driving. This includes reliable heating, ventilation, and air conditioning (HVAC), as well as power for lighting, appliances, and personal electronics. Thermo King APUs are designed specifically to meet these needs, providing an efficient and environmentally responsible alternative to idling the primary engine (Figure 1).

Figure 1: APUs provide energy for essential truck functions while stationary—such as HVAC, lighting, appliances, and other driver comforts—to prevent the need for inefficient engine idling.

While initially viewed as luxuries, APUs have become an imperative investment for fleets of all sizes. The multifaceted benefits include:

- Decreased fuel consumption: APUs consume a fraction of the fuel used by an idling tractor engine, providing obvious cost savings.

- Reduced emissions: By burning less fuel more efficiently, APUs produce fewer emissions than tractor engines, enabling fleets to meet stringent environmental regulatory standards.

- Lower maintenance costs: Shifting non- propulsion runtime from the main engine to the APU reduces wear and tear on expensive powertrain components, extending maintenance intervals and the overall tractor lifecycle.

- Enhanced driver comfort and satisfaction: A quiet, climate-controlled cab with reliable power for amenities improves quality of life on the road for drivers, a critical factor in recruitment and retention.

- Regulatory compliance: APUs help fleets comply with the patchwork of local, state, and federal anti-idling regulations in North America.

There is a diverse range of APU solutions on the market, including high-efficiency diesel units and all-electric battery-powered systems. This variety provides options for fleet operators to select the optimal technology to meet their unique operational requirements, routes, and sustainability objectives.

Compounding costs of engine idling

While necessary for driver rest and well-being, stationary periods present a significant operational dilemma for fleets. With APUs incapable of powering all needed in-cab appliances, drivers were forced to idle tractor engines, creating a cascade of financial and logistical issues.

Operational and financial inefficiencies

The sleeper cab is a driver’s home on the road, so ensuring comfort is important. Unfortunately, powering HVAC systems and auxiliary electronics often requires idling the tractor’s main engine, which is inefficient. A typical Class 8 truck engine consumes approximately one gallon of diesel fuel per hour of idling. Over a year, this can amount to thousands of gallons of wasted fuel per vehicle, inflating operating costs and eroding profit margins.

Furthermore, these unnecessary run hours accelerate wear on critical engine components. An engine that spends a significant portion of its time idling requires more frequent oil changes and filter replacements, and it may face premature overhauls, reducing its road-going lifespan and diminishing the truck’s resale value. The constant, low-load operation is also detrimental to modern exhaust aftertreatment systems, which can lead to costly repairs and extended downtime.

Regulatory hurdles and environmental responsibility

The environmental impact of idling is a primary concern for regulators and the public. In response to air quality and noise concerns, governments at all levels have introduced various anti-idling decrees, dating back to the 1980s. Currently, over 30 US states and numerous municipalities enforce laws that restrict engine idling, typically limiting it to as little as three to five minutes. These regulations, which often come with steep financial penalties, create a significant compliance burden for fleets operating across multiple jurisdictions.

Two of the most stringent regulatory frameworks impacting the industry in North America are those set by the California Air Resources Board (CARB) and the US Environmental Protection Agency (EPA). For example, CARB requires that any truck built after 2007 with a diesel-fueled APU is either fitted with an approved diesel particulate filter (DPF) on the unit, or its exhaust is plumbed into the vehicle’s aftertreatment system.

The EPA’s Tier 4 emission standards mandate a dramatic reduction in particulate matter (PM) and nitrogen oxides (NOx) compared to previous generations of engines, driving the need for advanced emission control technologies.

Navigating regulations without a viable alternative to idling is a significant challenge for fleet managers, exposing them to financial risk and operational disruption.

Driver quality of life

Beyond the mechanical and regulatory issues, engine idling directly impacts the driver. The continuous noise and vibration from an idling tractor engine can degrade the quality of rest, which can lead to fatigue and reduced driver alertness on the road. The constant drone of an engine can also be a nuisance at crowded rest stops, potentially affecting the entire driver community.

Providing a quiet and comfortable environment is desired to help ensure drivers are well-rested, safe, and satisfied with their working conditions.

The TriPac solution

As the transportation industry leader in temperature control solutions, Thermo King engineered the TriPac APU series to directly address the challenges of conventional auxiliary power, delivering a return on investment through superior efficiency, reliability, and performance. Offering both a best-in-class diesel model and an advanced all-electric option, the TriPac family provides convenient solutions to meet any fleet’s needs.

Fitting trucks with TriPac APUs is an investment in fleet-wide efficiency, as well as peace of mind by putting regulatory compliance concerns to rest. The diesel variant can provide substantial fuel savings, consuming approximately 75% less fuel per hour than an idling tractor engine. This translates to reductions as high as 2,500 gallons of fuel per year based on typical operation.

Furthermore, by offloading thousands of hours of runtime from the tractor’s engine to the APU, fleets preserve their most valuable mechanical asset for its intended purpose: moving freight. This reduction in wear not only lowers maintenance costs and increases uptime, but it also contributes to a higher resale value when the time comes to cycle out the tractor.

3rd Generation TriPac delivers top-tier diesel APU performance

The 3rd generation TriPac is the culmination of decades of engineering refinement, delivering comfort and performance for fleets that demand the most in a diesel APU (Figure 2). At the system’s heart is a robust, EPA Tier 4 compliant two-cylinder diesel engine, constructed for quiet efficiency and durability. This engine powers a Thermo King QP15HD air conditioning compressor to provide a best-in-class 13,000 BTU/hr of cooling capacity, ensuring a comfortable cab environment, even in extreme summer heat. This is paired standard with a powerful 7,500 BTU/hr fuel-powered heater for yearround climate control, with a high-output 13,600 BTU/hr version available for moving freight in the coldest climates.

Figure 2: The Thermo King 3rd Generation TriPac APU is an EPA Tier 4 compliant high-efficiency diesel unit with best-in-class cooling and heating, along with the capability to power auxiliary in-cab electronic devices.

A 120-amp alternator manages the system’s electrical needs, providing ample power to charge truck batteries and power in-cab devices. And the entire unit is built with serviceable components, including streamlined wire harnesses and connectors, to improve reliability and simplify maintenance.

This robust system is controlled through a sophisticated yet streamlined operator interface, featuring an enhanced color digital display (Figure 3). This digital human-machine interface (HMI) gives drivers greater control and at-a-glance insight into their environment, utilizing tactile push buttons, large temperature readouts, function icons, toggling menus, and plain language readouts for intuitive in-cab controls.

Figure 3: The 3rd Generation TriPac HMI features a full-function layout with a color digital display, providing drivers with at-a-glance insights about their environment, and plain language readouts for intuitive incab controls.

The standard EPA Tier 4 compliant 3rd Generation TriPac meets regulatory requirements in 49 states. For fleets operating nationwide in the U.S., this unit is available from the factory with an aftertreatment device (ATD) incorporated to meet the most stringent regulatory requirements from CARB. These certifications give fleets maximum logistical freedom, eliminating compliance concerns so they can quickly dispatch trucks to any location.

Furthermore, the 3rd Generation TriPac is available with TracKing® Telematics, providing two-way realtime visibility into APU performance, along with alarm notifications and maintenance reminders to support continued efficient APU function. This information provides precise APU data while trucks are on the road, empowering fleet operators to make informed business decisions and enhance operational efficiency (Figure 4).

Additionally, TracKing Telematics provides run hour tracking, fuel tax reporting, and an application programming interface (API) for integrating with existing fleet management system software. These features empower fleet managers to transition from reactive to proactive maintenance models, using APU run hour and cabin temperature data to schedule service, while leveraging automated fuel tax reporting and over-the-air software updates to assist with administrative responsibilities and enhance unit uptime through data-driven insights.

Thermo King’s TracKing Telematics asset connectivity solutions piece together telematics across a wide range of products, providing the ability to track and trace deliveries, monitor historical operational data, consistently meet regulatory requirements, and respond whenever challenges arise.

Figure 4: TracKing Telematics provides an in-depth statistical view of operational and cost savings data, clearly showing equipment impact across a fleet.

TriPac Envidia sets the all-electric benchmark for driver comfort

For fleets prioritizing zero-emission performance and quiet operation, the 2nd generation TriPac Envidia APU improves upon the industry standard (Figure 5). As an all-electric, battery-based system, Envidia offers clean and quiet comfort, running with less noise than any engine-based APU to provide an environment conducive to lasting rest. This can promote driver well-being and restoration to increase alertness on the road, while also providing a considerate presence at crowded rest stops. It is expertly designed to meet nationwide anti-idle and zero-emission regulations, including current CARB requirements.

Figure 5: The Thermo King TriPac Envidia APU is an all-electric, battery-based system, providing zeroemission and quiet comfort in the truck cab.

The unit runs on a robust bank of Thermo King’s proprietary NXT batteries, which feature advanced dry cell technology for higher efficiency, longer lifecycle, and a typical lower total cost of ownership compared to conventional batteries. This powerful battery system delivers 8,000 BTU/hr of air conditioning, engineered specifically to overcome the historical challenges of limited runtime and power that have impacted earlier electric APUs. For year-round operation, the Envidia can be integrated with optional fuel-fired heaters, available in both 7,500 BTU/hr and high-output 13,600 BTU/hr configurations, providing the same powerful heating performance found in its diesel counterpart.

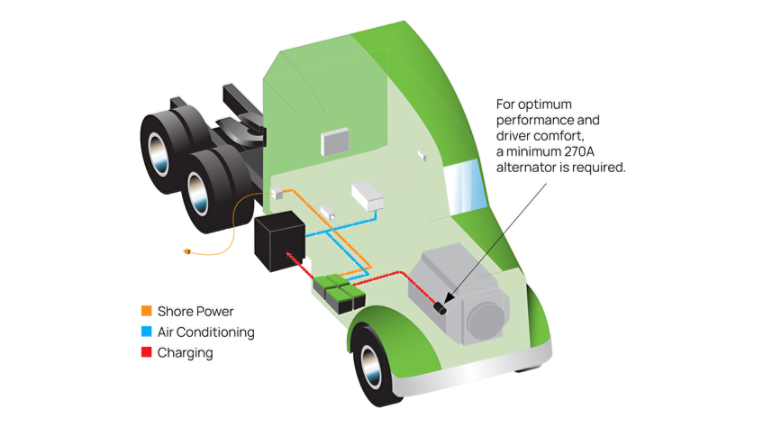

Envidia incorporates flexible charging and sophisticated power management to enhance runtime. When plugged into shore power, the unit allows running HVAC while simultaneously charging both truck and Envidia batteries (Figure 6). This helps ensure that the tractor and APU are fully prepared for the journey ahead when leaving the loading dock.

Figure 6: The Envidia APU incorporates flexible charging and sophisticated power management, enabling simultaneous HVAC operation and charging of both the truck and APU batteries when connected to shore power.

For greater autonomy and efficiency, the system can be equipped with roof-mounted ThermoLite® solar panels (Figure 7). These panels assist in extending battery life between charges by providing a constant trickle charge, which can also reduce long-term battery degradation and maintenance expenses by continuously conditioning the battery system.

Figure 7: ThermoLite solar panels deliver clean and reliable performance in a wide variety of applications, resulting in longer battery life, lower fuel consumption, and reduced emissions.

Generation TriPac diesel APU, providing power to maintain tractor battery charging and reducing required runtime in monitor mode.

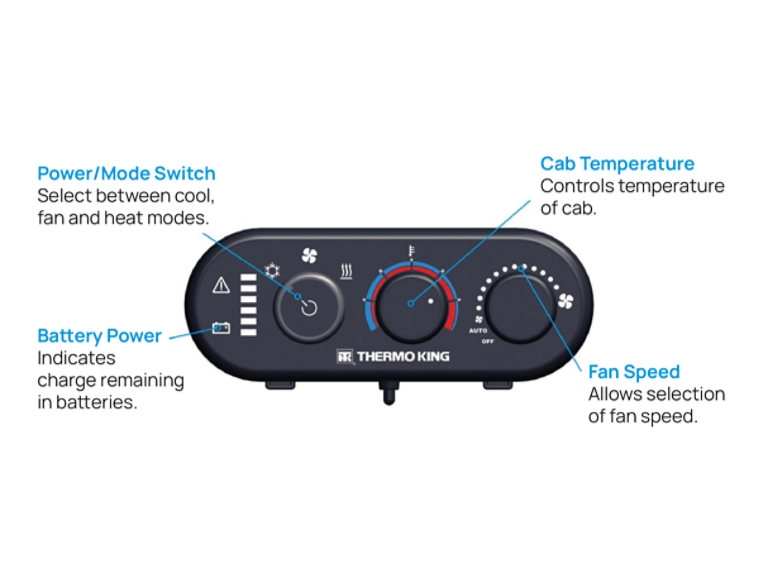

The advanced Envidia power system is controlled by a simple and intuitive three-knob HMI to select HVAC mode, cab temperature, and fan speed, helping drivers easily manage their comfort and the APU battery level (Figure 8).

Figure 8: Thermo King TriPac Envidia is equipped with a simple and intuitive three-knob HMI for heating and cooling control, with battery level indicator.

These features position Envidia not merely as a potential replacement for diesel APUs, but as a technologically enhanced alternative for sustainable fleet operations.

Propelling profitability and driver retention

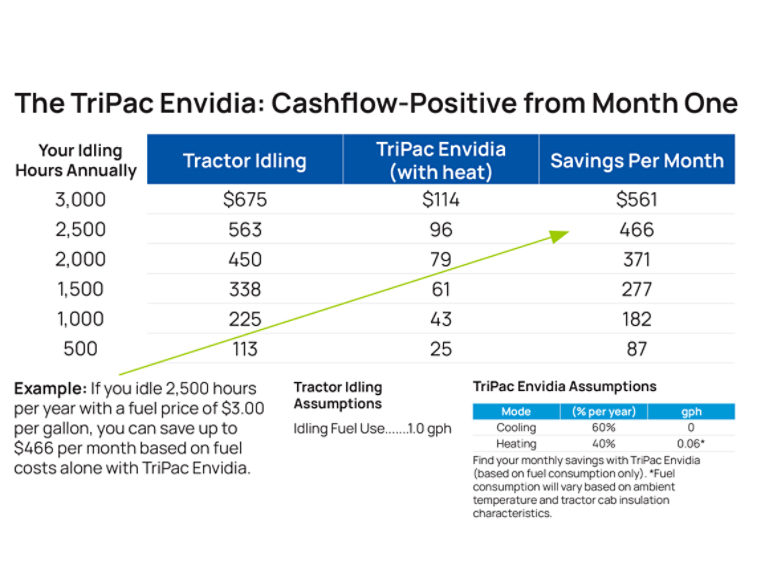

Fleet operators are adopting Thermo King TriPac APUs to directly bolster their bottom lines and strengthen their workforces (Table 1).

Table 1: Example monthly operational cost savings chart for a single truck equipped with a TriPac Envidia APU, compared to idling the tractor engine.

Fleet operator and driver testimonials consistently highlight these long-term benefits as key advantages of the TriPac system. Carey Pritt, director of maintenance at Danny Herman Trucking, affirms “The Third Gen TriPac not only preserves the health of our trucks’ engines and aftertreatment systems, but it also extends service intervals and prevents avoidable breakdowns. This leads to fewer road calls, lower repair costs, and more predictable maintenance planning, which translates to increased uptime and stronger overall performance.”

The financial return on investment is evident. Fleets can use tools like Thermo King’s Fuel Savings Calculator to estimate savings based on their specific operational parameters, including idling hours and local fuel prices. Beyond fuel savings, the value proposition extends to increased resale values from reduced engine wear, along with lower overall maintenance expenditures.

Equally important is the impact on driver satisfaction and retention. In the highly competitive market for qualified drivers, a comfortable work environment is a clear differentiator among employers.

Pritt continues, stating that “The TriPac 3 is more than just an accessory; it’s an investment in operational efficiency, driver comfort, and long-term cost savings. It enables our company to operate smarter, reduce unnecessary expenses, and provide drivers with a comfortable environment because it delivers dependable heating, cooling, and power without relying on the truck’s engine. This gives drivers the comfort and stability they expect during rest periods, helping with retention, satisfaction, and overall productivity. When drivers can rest well, they perform better, and that safety benefit is invaluable for every operation. These benefits are a win for our drivers, and a win for the company as well.”

By offering a quiet, climate-controlled rest environment with ample power for personal devices, fleets equipped with TriPac APUs demonstrate a commitment to their drivers’ well-being.

Partner with an industry leader

Overcoming the challenges of rising fuel costs, stringent air quality regulations, and driver shortages require intelligent and forward-thinking solutions. Engine idling can become a relic of a bygone era, as its continuation poses a drain on fleet profitability and global sustainability. Modern APUs provide solutions to this problem, and Thermo King leads the industry with high-powered yet efficient technology.

The Thermo King APU family, with the regulatorycertified diesel 3rd Generation TriPac and the clean and quiet electric Envidia, delivers a comprehensive portfolio to assist with diverse needs in the trucking industry. These systems eliminate unproductive idling, reduce fuel consumption, limit maintenance costs, ensure regulatory compliance, and enhance driver comfort, providing a clear value proposition.

Thermo King is more than a supplier; it is your partner in fleet success. With a vast dealer network— comprised of over 180 locations, more than 800 service bays, over 500 mobile service trucks, aftermarket parts and accessories, and more than 900 factory-certified technicians—and a legacy of innovation, Thermo King provides the expertise and support to help move its customers’ fleets efficiently to the next level, tailored to their unique operational needs.