T-Series

T-Series

The most reliable HVAC system for transit is now better than ever.

High performance and reliability for more than 30 years. T-Series: The HVAC design that changed an industry.

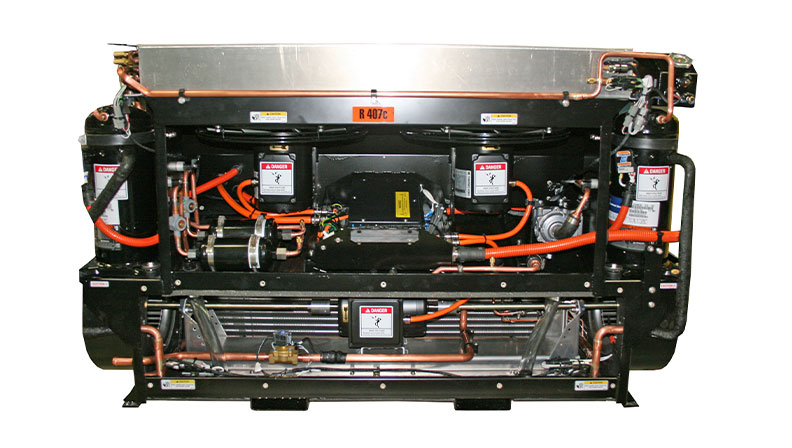

Features

Low life cycle costs

Performance proven components provide long service life and minimum maintenance for low life cycle costs.

Lightweight

Lightweight all-aluminum frame, blowers, coil headers, and compressor reduce bus stress and fuel consumption.

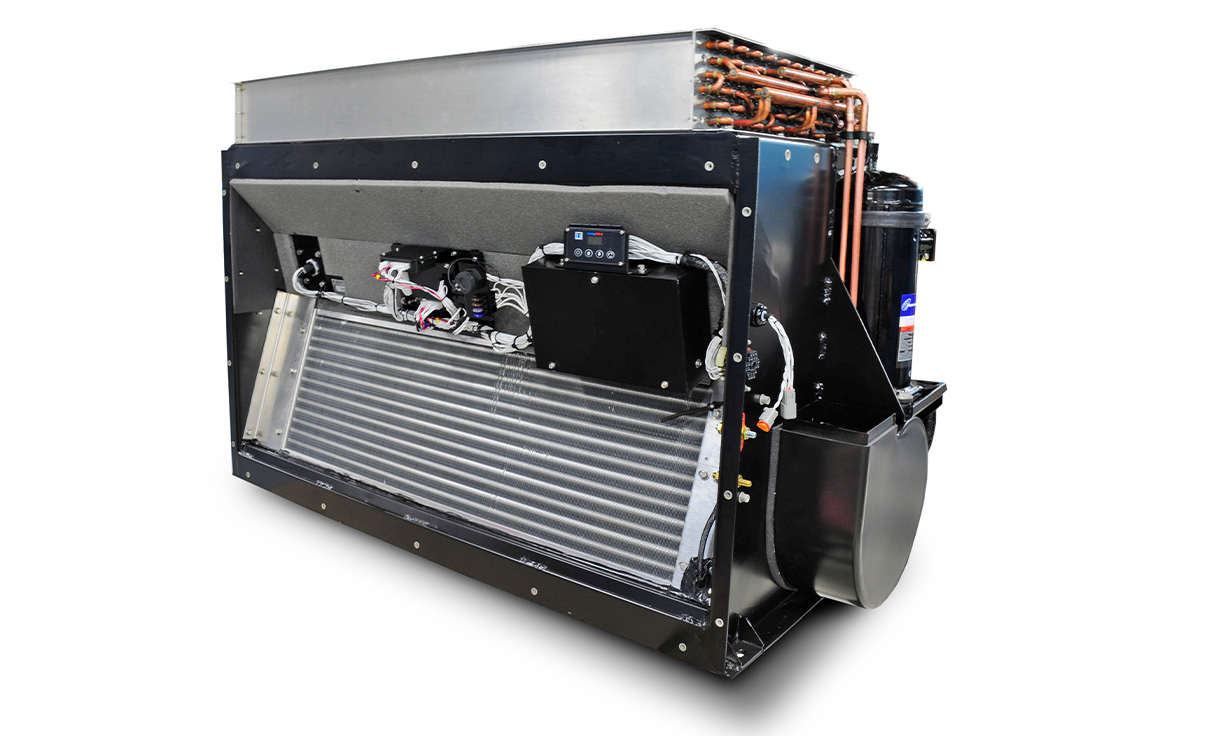

Easy to service

Convenient service access to all major components. Simplified electrical troubleshooting with microprocessor controls. Removable access panels and a convenient rear window location provide easy access to unit components for repairs or maintenance.

Same major components and options across platform.

T Series units have many of the same internal components in the electrical and refrigeration systems, assuring a readily available supply of parts and parts interchangeability to lower costs and minimize downtime.

Easy to install

T Series units are easy to install and service because of the compact, one-piece design.

Proven dependability

You know you’re getting a dependable, reliable bus air conditioning and heating system that can lower your operating and maintenance costs and keep your bus riders cool.

TEA Series

For use on standard diesel engine-driven buses.

TE Series

For use on hybrid electric and all-electric buses.

Benefits of the T-Series

Why pay for more than you want. Thermo King provides standard features designed to meet your needs.

Intelligare III™ control system

- Multiple zones can be controlled using identical expansion modules via CAN network and interconnected software

- Expanded CAN communication capability to plug directly into the vehicle’s J1939 network

- Operator-friendly display and pressure modules for improved control and diagnostics

High-performance R-407C or R-134A

- Environmentally safe alternatives with zero ODP

The Thermo King X430 compressor

- Engineered exclusively for transport applications

- Built for extended service life

- Field repairable

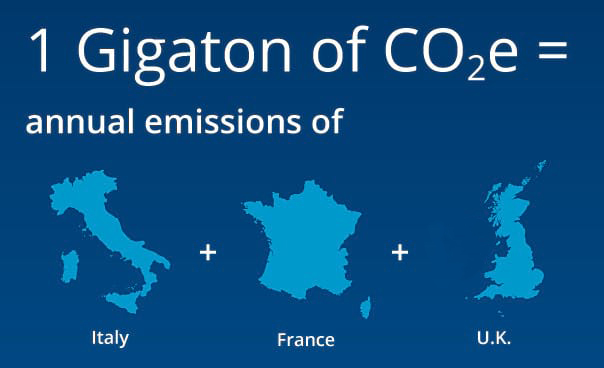

Committed to sustainability

Next generation TE Series electric bus HVAC units are part of our all-electric portfolio, called evolve™. The evolve portfolio aligns with our customers’ goals to transition to more sustainable solutions for their fleets, and will help advance Trane Technologies’ 2030 Sustainability Commitments, including its Gigaton Challenge to reduce customer greenhouse gas emissions by 1 billion metric tons.

Resources

Brochure / Flyer

-

7MB

Support wherever you need us

With the Thermo King Dealer Network, you have access to service and proactive maintenance at over 200 locations. Find the support that’s closest to you with the online dealer locator—complete with contact details and service offerings.